-

English

English

-

Español

Español

-

Português

Português

-

русский

русский

-

français

français

-

日本語

日本語

-

Deutsch

Deutsch

-

Tiếng Việt

Tiếng Việt

-

Italiano

Italiano

-

Nederlands

Nederlands

-

ไทย

ไทย

-

Polski

Polski

-

한국어

한국어

-

Svenska

Svenska

-

magyar

magyar

-

Malay

Malay

-

Dansk

Dansk

-

Suomi

Suomi

-

عربى

عربى

-

norsk

norsk

-

اردو

اردو

-

čeština

čeština

-

Ελληνικά

Ελληνικά

-

Javanese

Javanese

-

български

български

-

ລາວ

ລາວ

-

Latine

Latine

-

Euskal

Euskal

-

Azərbaycan

Azərbaycan

-

slovenský

slovenský

-

Македонски

Македонски

-

Eesti Keel

Eesti Keel

-

Српски

Српски

-

Afrikaans

Afrikaans

-

עִברִית

עִברִית

-

icelandic

icelandic

-

Беларус

Беларус

-

Malti

Malti

-

lugha ya Kiswahili

lugha ya Kiswahili

-

አማርኛ

አማርኛ

-

Frysk

Frysk

-

ជនជាតិខ្មែរ

ជនជាតិខ្មែរ

-

ಕನ್ನಡ

ಕನ್ನಡ

-

Corsa

Corsa

-

Kurdî

Kurdî

-

മലയാളം

മലയാളം

-

Hmong

Hmong

-

Cebuano

Cebuano

-

Hawaiian

Hawaiian

-

Shinra

Shinra

Products

New Products

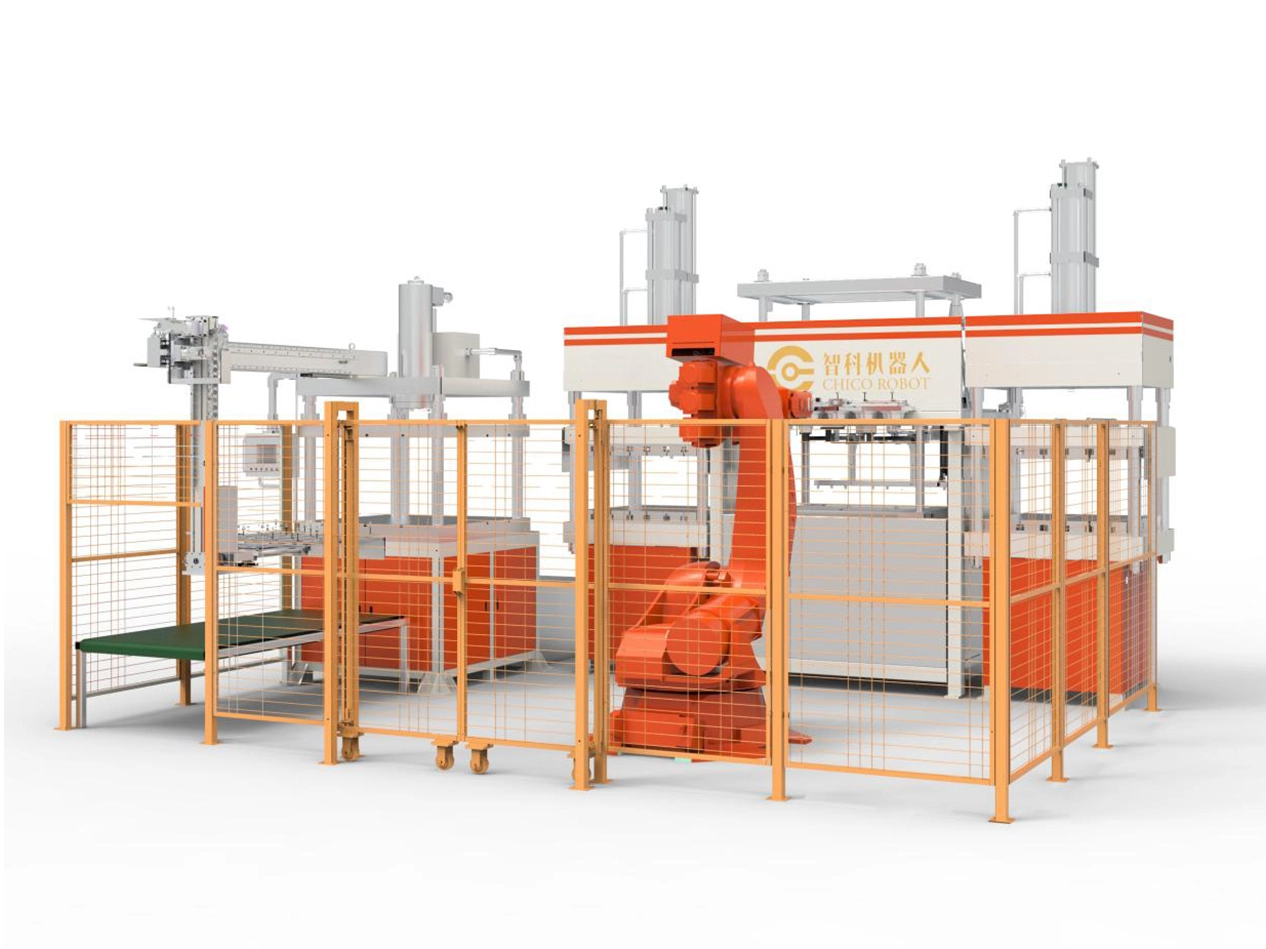

Fully Automatic Multi-articulated Robot Paper Mold Tableware Forming Cutting Edge Integrated Machine

Send Inquiry

Product Description

Cutting Edge Integrated Machine

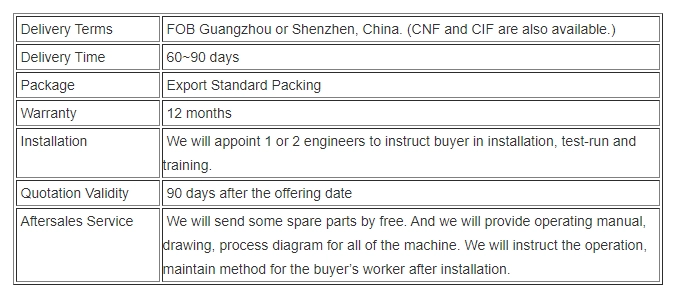

1). Equipment name:Fully Automatic Multi-articulated Robot Paper Mold Tableware Forming Cutting Edge Integrated Machine

2). Applicable products: pulp molded tableware products

3). Functions: forming, transferring, trimming, stacking and conveying are completed in one.

4). Forming method: vacuum suction

5). Layout size: 950mm*950mm

6). Heating method: heat transfer oil or electric heating

7). Maximum boosting pressure of sizing machine: gas-liquid boosting 40t

8). Trimming machine pressure: 60t

9). Product transfer mode: external transfer of six axis multi joint robot

Control mode: plc+ touch screen

10). Maximum height of production product: 80mm

Other specifications and models of equipment

|

Equipment size |

Boost pressure |

yield |

|

800*680mm |

30T |

15~20kg/h |

|

950*950mm |

40T |

30~35kg/h |

|

1100*950mm |

50T |

35~50kg/h |

2. Equipment characteristics of Fully Automatic Pulp Molding Tableware Forming Cutting Machine

|

Zhike robot

|

contrast

|

Universal manufacturing enterprise

|

|

Molding machine: the main components and slurry box are made of high-quality 304 stainless steel, which is rust proof, corrosion-resistant and has a long service life

|

VS

|

Ordinary carbon steel, easy to rust, short service life

|

|

Molding machine: system matching and optimization design to improve production capacity

|

VS

|

Mismatch of finalized production tempo, affecting production capacity

|

|

Molding machine: with gas-liquid booster cylinder, the middle plate will not drop suddenly, and the safety is high

|

VS

|

With ordinary booster cylinder, the middle plate may drop suddenly when the air supply pressure is low, so the safety is low

|

|

Online trimming: equipped with multi joint and trimming and blanking manipulator, it can realize online trimming and automatic stacking

|

VS

|

Manual reclaiming

|

|

Online trimming: equipped with pneumatic finished product receiving platform, which can realize product receiving without stopping

|

VS

|

Manual picking after shutdown

|

|

Fully automated production continues to be stable

|

VS

|

Continuous unstable production due to manual transfer

|

|

Number of single operator: 4-6

|

VS

|

One person, one machine

|

|

Reduce labor force and return on investment

|

VS

|

Labor shortage

|