-

English

English

-

Español

Español

-

Português

Português

-

русский

русский

-

français

français

-

日本語

日本語

-

Deutsch

Deutsch

-

Tiếng Việt

Tiếng Việt

-

Italiano

Italiano

-

Nederlands

Nederlands

-

ไทย

ไทย

-

Polski

Polski

-

한국어

한국어

-

Svenska

Svenska

-

magyar

magyar

-

Malay

Malay

-

Dansk

Dansk

-

Suomi

Suomi

-

عربى

عربى

-

norsk

norsk

-

اردو

اردو

-

čeština

čeština

-

Ελληνικά

Ελληνικά

-

Javanese

Javanese

-

български

български

-

ລາວ

ລາວ

-

Latine

Latine

-

Euskal

Euskal

-

Azərbaycan

Azərbaycan

-

slovenský

slovenský

-

Македонски

Македонски

-

Eesti Keel

Eesti Keel

-

Српски

Српски

-

Afrikaans

Afrikaans

-

עִברִית

עִברִית

-

icelandic

icelandic

-

Беларус

Беларус

-

Malti

Malti

-

lugha ya Kiswahili

lugha ya Kiswahili

-

አማርኛ

አማርኛ

-

Frysk

Frysk

-

ជនជាតិខ្មែរ

ជនជាតិខ្មែរ

-

ಕನ್ನಡ

ಕನ್ನಡ

-

Corsa

Corsa

-

Kurdî

Kurdî

-

മലയാളം

മലയാളം

-

Hmong

Hmong

-

Cebuano

Cebuano

-

Hawaiian

Hawaiian

-

Shinra

Shinra

Products

New Products

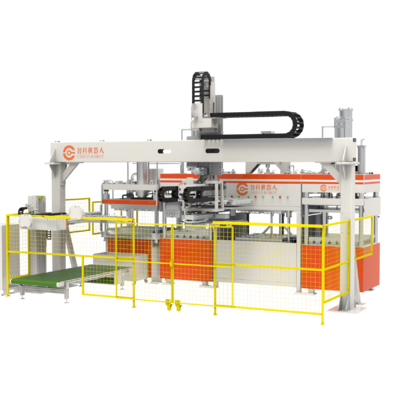

Pulp molding machine | pulp molding equipment

Send Inquiry

Product Description

Pulp molding machine

1. Product introduction of Pulp Molding Machine Equipment

Pulp Molding Machine is a piece of equipment used to manufacture pulp products, usually used to produce packaging products such as paper plates, paper bowls, paper trays, etc. It is an environmentally friendly production process that uses degradable raw materials such as waste paper to make paper products of various shapes through processes such as molding and drying.

2. Product features of Pulp Molding Machine Equipment

1). Strong plasticity: The pulp forming machine can manufacture products of various shapes and sizes to adapt to different packaging needs.

)2. Environmental protection: Using degradable waste paper as raw materials helps reduce the impact on the environment and promotes sustainable development.

3). High degree of automation: Modern pulp forming machines usually have the characteristics of high automation, and automatic operations can be realized from the feeding of pulp to the discharging of finished products.

4). Efficient production: The rapid molding and drying process makes the production efficiency higher and is suitable for large-scale production needs.

5). Relatively low cost: Due to the use of renewable raw materials such as waste paper and efficient and automated production processes, the cost is relatively low.

3.Advantages of Pulp Molding Machine Equipment

1). Sustainable development: The use of renewable raw materials such as waste paper helps reduce dependence on forest resources and promote sustainable development.

2). Customized production: The pulp forming machine can manufacture products of various shapes and specifications according to customer needs, achieving customized production.

3). Strong adaptability: It is suitable for producing various packaging products, such as food packaging, electronic product packaging, etc., and has a wide range of application fields.

4). Reduce waste: Waste paper can be recycled and reused during the manufacturing process to reduce waste generation.

4.Application of Pulp Molding Machine Equipment

1). Food packaging: Manufacturing paper trays, paper plates, paper bowls and other products used for food packaging.

2). Electronic product packaging: Produce pulp products suitable for transportation and packaging of electronic products.

3). Medical supplies packaging: manufacturing packaging boxes, trays, etc. for medical devices.

4). Agricultural field: Producing pulp products used for raising seedlings and transporting agricultural products.

5). Environmentally friendly tableware: Manufacture environmentally friendly paper tableware, such as paper lunch boxes, tableware, etc.

5.FAQ

1).What raw materials can be used for pulp forming machine?

The pulp forming machine mainly uses renewable raw materials such as waste paper, waste cardboard, and waste paper boxes.

2). Is the production process environmentally friendly?

Yes, the pulp forming machine uses environmentally friendly raw materials, produces less waste during the manufacturing process, and meets environmental protection requirements.

3).What is the strength of pulp products?

The strength of pulp products depends on the quality of the raw materials and production process. Generally speaking, they can provide sufficient strength to meet packaging needs.

4).Is the production process automated?

Most pulp forming machines have a highly automated production process, and can realize automated operations from pulp forming to drying.